Understanding complexities of modern engineering and construction can be daunting. ‘What is structural load mean?’ ‘What is a load-bearing cross section?’ Or, ‘What is galvalume metal?’ All these technical terms and questions can have you clicking on the back button of your browser before finally resigning from the thought of custom construction and settling for whatever monstrosity the ‘Big Box’ stores are peddling these days. But you don’t need a Master’s in Civil Engineering to know what constitutes a quality metal building. And what you probably don’t understand is the intrinsic beauty and strength of an arch building. Arches have been around for a long time. It’s sort of like the wheel – improved upon, but never reinvented. While we didn’t invent the arch, we have maximized its structural efficiency. An A-model steel arch building is the perfect example of how we’ve accentuated a time honored modern marvel.

What Makes the A-Model Steel Arch Building So Special

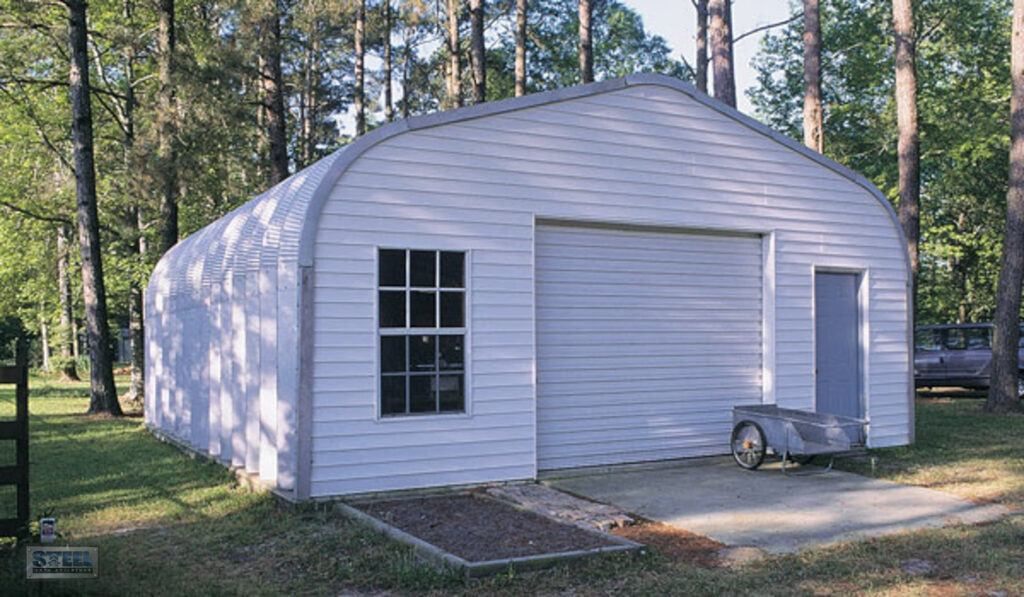

If you look closely at the above photo of our signature A-Model Steel Arch building, you might notice a subtle but important deviation near the peak of the building. While traditional arch buildings make a standard uninterrupted semicircle from end-to-end, an A-style building has a peaked center, which allows for extra headway at the top. While it may not sound like a lot, superficially, this extra six inches to a foot of space can mean the difference when it comes to storing large tractors with tall driver compartments or smoke stacks. Having a peaked center also means you could fit an extra few bales of hay for the winter. Might not sound like much today, but you will be thanking yourself in early April when the ground remains frozen and you still have a dozen head of cattle to feed before the next growing season.

Advancements in Engineering Without Skimping on Integrity

But as you might recall from your high school history class, “Aren’t arches perfect the way the are? Why are you changing the most distinguishable trait of this Roman classic?” While it’s true the arch was basically perfected millennia ago, changes in building materials have allowed for even greater enhancement and durability. Originally, early builders had to rely on stone and brick for erecting towering arches. They literally had to make the best of what they had to work with. The Industrial Revolution introduced steel, and the arch celebrated a structural renaissance.

Arches were stronger than ever before, but steel girders are never easy to bend, and powerful support beams were still needed to hold everything together. In the end, early steel arches were no more malleable than the stone predecessors. It was back to the drawing board for industrial engineers. But rapid advancements in metallurgy and machining allowed for the introduction of thinner sheets of steel that were every bit of strong as earlier iterations. This means these sheets of steel paneling can be firmly fastened together like the links of a chain, which give the building greater flexibility without sacrificing strength in protection.

Where Flexibility Meets Strength

The A-Model Steel Arch building puts the ‘A’ in versatility. You might not see the capital A at first, but you if you look close enough, it peaks right in the middle, just like a superior construct steel arch building. The A-Model Steel arch building, however, is more than just a superstructure shell. It’s a complete building. You don’t have to settle just for the roof, as countless customers have opted for closed ends to make the perfect garage, metal workshop or warehouse. Our buildings have been used for everything from barns, batting cages, retail stores, aircraft hangars, to office space, classrooms, storage complexes and manufacturing facilities. You could even hire a contractor to completely finish out the metal building’s interior to make the ideal tiny home or prefabricated living quarters and additions. That might actually be the more cost-effective option the way real estate prices continue to rise.